Hydraulic Cylinders

Wrong Selection of

Hydraulic Cylinder Companies

and Purchase of Wrong Hydraulic Cylinder

HAS RESULTED IN LOSSES OF

- Rs. 1,30,000 ($1,750) to a paper mill machinery supplier as a pair of hydraulic cylinders could not lift the required load.

- Rs. 53,000 ($705) in replacement cost as the hydraulic cylinder made out of untested steel developed cracks and started leaking after 3 months of service.

- Over Rs. 1 crore ($133,300) as the launch of a car was delayed as a critical material handling cylinder was not manufactured on time.

- Rs. 81,00,000 ($108,000) on account of project delay as a long delivery hydraulic cylinder was found to be 5mm longer then the approved drawing & would not fit at the time of machine assembly.

- Rs. 3,60,000 ($4,800) a heating equipment expert had to face embarrassment when the spare seal kit did not fit in the failed cylinders. They had to send technicians abroad to resolve the problems.

- Oil spill from a leaky hydraulic cylinders resulted in rejection of a container of paper plates in U.K. resulting in losses of over Rs. 1 crore($ 133,000) & black listing of the supplier.

ACE’s wide exposure as

Hydraulic Cylinder suppliers

makes us the RIGHT CHOICE in…

- Helping in selection of the right specification to solve your problem/application.

- Using only tested & inspected raw materials ensures crack free parts no leakage during service.

- Inspection at each stage of manufacturing ensures a quality product that does not fail or cause oil spills.

- Final/ Pre dispatch inspection ensures that the end product matches the drawing 100%.

- On Time delivery is ensured using PMS – Project Management Systems.

- All drawings data & seal details safely stored.

ACE AUTOMATION ENGINEERS

Your Expert

Industrial Hydraulic Cylinder Manufacturer

WHY CHOOSE ACE AS YOUR PREFERRED CHOICE OF HYDRAULIC CYLINDER MANUFACTURER?

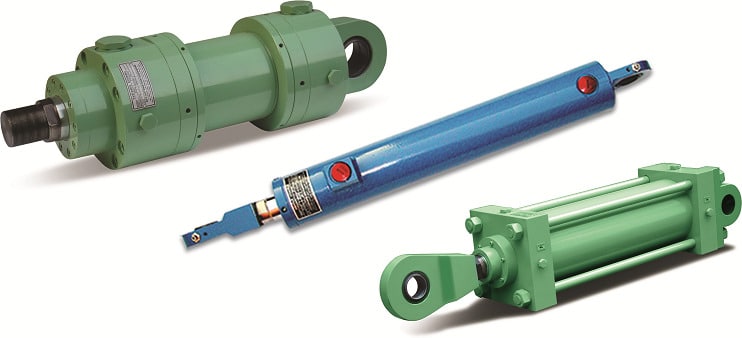

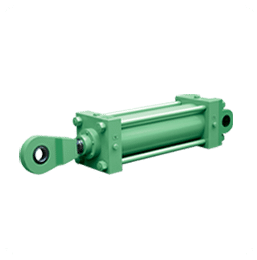

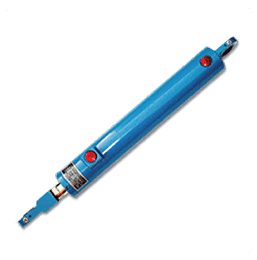

TIE ROD DESIGN DOUBLE ACTING HYDRAULIC CYLINDER

Double Acting Hydraulic Actuator

are ideal for Industrial Machines. They are easy to maintain & customise.

Available in 5 mounting styles. Working Pressure: 160 Kgf/cm2 (BAR)

WELDED CONSTRUCTION DOUBLE ACTING HYDRAULIC CYLINDER

Double Acting Hydraulic Actuator

are ideal for Industrial Applications requiring larger quantities.

Easy to mass produce & commonly used in 2 mounting styles. Working Pressure: 160 Kgf/cm2 (BAR)

HEAVY/MILL DUTY DOUBLE ACTING HYDRAULIC CYLINDER

Double Acting Hydraulic Actuator

are ideal for Mill Duty Applications.

Ideal for 24 x 7 working. Available in 5 mounting styles. Working Pressure: 210 Kgf/cm2 (BAR).

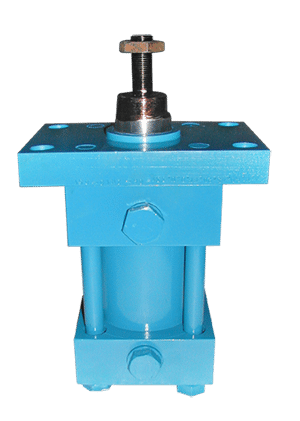

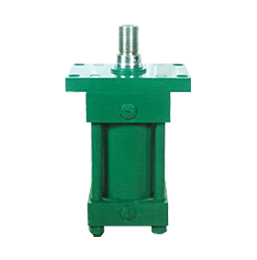

HYDRAULIC PRESS CYLINDER

Hydraulic Press Cylinder Manufacturers

since 1992. These are ideal for Hydraulic Presses.

Available in Front Flange mounting style. Working Pressure: 300 Kgf/cm2 (BAR).